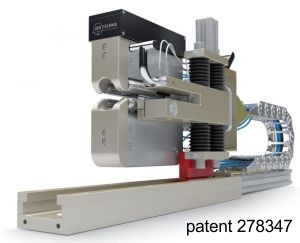

MTP - Continuous Strip Thickness Gauge with Automatic Drive

This high-endurance heavy-duty gauge is designed for precision continuous online contact measurement of metal as well as non-metallic strip thickness (continuous thickness mesurement). Types: MTP-1301A, MTP-2001A, MTP-3001A.

Tactile thickness measurement

There is the company´s own microwave technology with no electronic components, coils and ferrites inside the tactile highly resistant sensors. The sensors are absolute, very stable, with linearity of < 0.01% and resolution of 0.1 µm. Therefore, the thickness gauges do not require zeroing before/after measuring that tends to be a source of very inaccurate measurement if it is zeroed with impurities between contacts. Thanks to cooling the sensors and contacts through the sensor body, strip thickness can be measured at temperatures of 250°C with a temperature dependence of ≤ 1 µm/200°C without need of heating the measuring head. Measuring contacts made of sintered diamond are typically used for decades of years without replacement even in heavy-duty environment.

The gauge sliding in the operating position on strips of varied lengths and the gauge operation monitoring is carried out by SIEMENS automatic drive using pneumatic system. The design of the diamond contacts, which are permanently touching the measured strip, secures they do not impair the appearance of the material and have long service life. The pneumatic thrust of the contacts on the strip can be continuously controlled.

This continuous gauge was developed as an absolute measuring device requiring no mechanical readjustment for the nominal thickness of the measured strip and its absolute measuring capability allows to use it also for precision calibration of other (e.g. contactless) gauges during the production process.

The control unit enables:

digital thickness on 7" touch panel display

digital thickness on 7" touch panel display- analogue display to show the deviation from the set nominal thickness

- setting and monitoring of lower and upper limits

- digital calibration of the gauge

- control of moving head into strip line

- anlogue outputs for AGC ± 20 mA (± 10V; 4 - 20 mA)

- serial data output module (RS-485, PROFIBUS, PROFINET,...)

Features:

- absolute digital display of the measured thickness

- independence of the measured material type

- no mechanical adjustment of the gauging head for nominal thickness

- easy operation

- 5 years warranty on diamond contacts

Optional accessories:

| Parameter | MTP-1301A (-2001A; 3001A) | MTP-1301AF (-2001AF; 3001AF) |

|---|---|---|

| Resolution | 0.001 mm .00001" |

0.0001 mm .00001" |

| Strip thickness range: | 0.005 - 9 mm, max. 20 mm .0002" - 0.35" |

0.005 - 2 mm .0002" - .08" |

| Max. thickness measurement error | ≤ 1 µm; ≤ 2 µm (> 2 mm) ≤ .00004"; ≤ .00008" |

≤ 0.5 µm ≤ .00002" |

| Max. measurement depth from the strip edge: | 130 mm (210 mm, 310 mm) 5.2" (8.2", 12.2") |

|

| Max. strip speed: | 900 m/min 3 000 ft/min |

|

Attached video

MTP-1301 - Strip thickness measurement on 200°C (390°F) hot strip:

MTP-1301A + MTP-2001AE (single line measurement + scanning head):

MTP-3001A strip thickness gauge:

Thickness gauge during strip breakage:

MTP-1302A-LH lead (Pb) strip thickness measurement:

Thickness gauge MTP-1302 (steel, rolling mill):

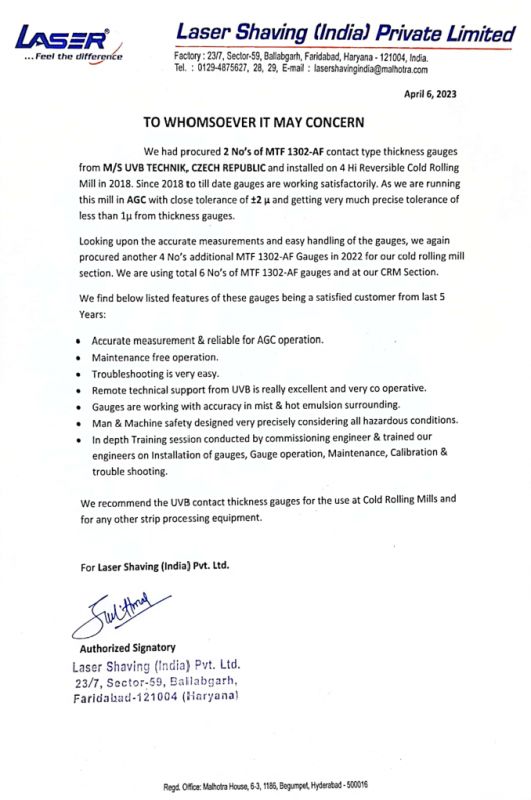

Reference letter

Attached files

- Catalogue_English – (3.44 MB)